AC Motors

Basic Parts and Principles

Electric motors convert electrical energy into mechanical motion by using magnetic forces to accelerate objects. Electricity comes in two flavors: AC and DC<ref>http://fweb/class-wiki/index.php/AC_vs._DC</ref>. Therefore, electric motors need to be able to utilize at least one of these in order to operate. As a general rule, AC and DC motors are constructed using slightly different parts because of the different behavior of the types of electricity. Lets first look at the parts in a generic AC motor and then discuss the role they play in making motion.

AC motors consist mainly of a stator and an armature<ref>http://hyperphysics.phy-astr.gsu.edu/hbase/magnetic/motorac.html</ref>. The stator is fixed inside the motor. Stators are almost always made using tightly wound wire in order to yield a high magnetic flux density. The second part is the rotor, which rotates to provide movement to whatever application is desired. The rotor can also use wound wire, through which current flows or a permanent magnet. In order to get this current to the rotor without tangling wires around the rotor, metal slip rings are used to complete the circuit<ref>http://hyperphysics.phy-astr.gsu.edu/hbase/magnetic/motorac.html</ref>.

Magnetic flux is created when current passes through the armature wires. Since the motor uses alternating current, the magnetic field will alternate the polarity. Both the stator and rotor produce magnetic fields. The basic interaction between magnetic fields indicates that opposite poles attract while like poles repel. All electric motors use this behavior to produce rotation. When the poles of the stator and rotor are the same, the force will push the two apart. Similarly, the stator and rotor will be pulled together. Motors use both of these simultaneously to impart motion to the rotor, to which the output shaft is attached. This rotation can be used to do useful mechanical work.

Synchronous AC Motors

Synchronous motors are termed "synchronous" because they inherently run at a constant velocity which is synchronized with the frequency of the AC power supply. These motors contain the same two basic components common to all motors: A rotor - the components that rotate, and a stator - the outside shell of the motor. The rotor can be made from either a permanent magnet or winding powered by a DC power source. When powered, this winding operates as a permanent magnet. The rotor has 2 poles in the simplest case, but can have many more depending on the application. The stator holds the armature winding which creates a pulsating magnetic field inside the motor. The armature winding can be either single or multi-phase depending on the configuration of the motor.

Synchronous motors create a torque from the magnetic field of the rotor interacting with the alternating field created by the armature. The field created by the armature is continuously changing because the coils are powered by an AC source. As the voltage in the windings swings from positive to negative, the magnetic field also shifts<ref>http://www.allaboutcircuits.com/vol_2/chpt_13/2.html</ref>. As this field shifts from north to south, the poles on the rotor inside of the motor will be either attracted or repelled from the coils of the armature. These attraction and repulsion forces create a torque which drives the rotor.

<ref>http://www.allaboutcircuits.com/vol_2/chpt_13/2.html</ref>

Synchronous motors are unique in that they are not self starting. This is because as soon as voltage is applied to the armature windings, the magnetic field varies at the frequency of power line. At start up, this field builds so quickly that the rotor can not get up to speed and synchronize with the varying armature winding. Several different methods can be used to start synchronous motors. First and most simply, a secondary motor can be used to start the rotor spinning at the rotational velocity corresponding to the frequency of field shift. As soon as the rotor achieves this velocity, it "snaps in" to synchronism and the secondary motor can be shut down or disconnected<ref>http://www.acsynchronousmotors.com/</ref>. Large Synchronous motors can also employ a separate starting mechanism in the rotor. A squirrel cage winding in the rotor can be fed with DC power through slip rings to bring the rotor up to speed<ref>http://www.electricmotors.machinedesign.com/guiEdits/Content/bdeee2/bdeee2_1-5.aspx</ref>. As the synchronous motor of this type starts, it essentially operates as a DC motor until it reaches the operating speed of the AC line.

Induction Motors

Induction motors are termed "induction" because there is no current supplied to the rotating coils in the rotor. The coils are closed loops which have large currents induced in them by the changing magnetic field produced in the stator coils<ref>http://hyperphysics.phy-astr.gsu.edu/HBASE/magnetic/indmot.html</ref>. This is different from synchronous AC motors which can have a current supplied onto the rotors.

There are two main types of induction motors. The first type is an adjustable-speed drive. These are used in the process control industry to adjust the speed of fans, compressors, pumps, blowers, etc. Also, these are used for electric traction in hybrid vehicles. The second type is a servo drive. These emulate the performance of a DC-motor drive and are used in machine tools, robotics, etc for highly precise control.

Squirrel-Cage Induction Motor

Squirrel cage motors are the most common forms of AC induction motors. They are commonly used in adjustable-speed applications. The cage has bars of copper or aluminum running the length of the rotor. In most working motors, the bars are skewed from following the axial direction of the motor to reduce noise. The bars are electrically shorted at each end of the rotor by end rings, and thus producing a cage like structure.

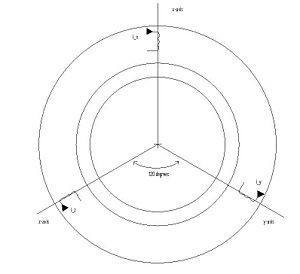

The stator of an induction motor has three windings which are displaced by 120o with respect to each other. <ref>Electric Drives by Ned Mohan</ref>

These stator windings are arranged around the rotor so that when energized with an alternating current they create a rotating magnetic field which sweep past the rotor. The changing magnetic field induces a current in the squirrel-cage of the rotor. The currents interact with the rotating magnetic field produced by the stator windings and produces a torque on the rotor.<ref>http://en.wikipedia.org/wiki/Induction_motor</ref>.

References:

<references/>

Authors:

Reviewers:

Readers:

Tyler Anderson