Hy-Gain (CDE) Rotor

Lessons Learned the Hard Way

I have used Ham series rotors for over 30 years now, sometimes to turn

some pretty big antennas. These rotors are usually fairly

inexpensive used (at least as rotors go), and if you don't have a large

budget,

you can make them work, provided you are careful to avoid some of their

pitfalls. I admit to learning all of these lessons the hard

way, and I'm ashamed of the number of years and re-occurrences it took

me to learn some of them. I have listed some here, and if you

have others, I would

like

to hear about them.

Some Ham Series Hints

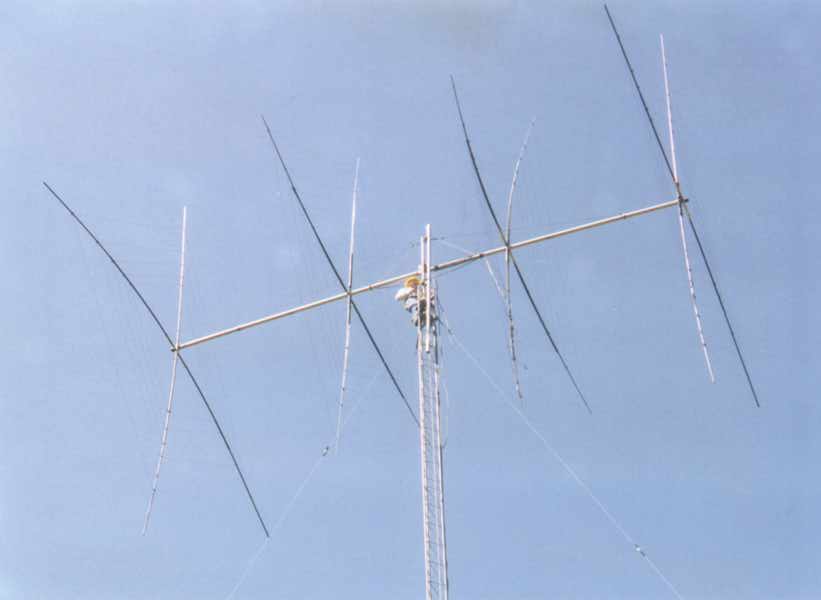

- If you want to turn a big antenna, I believe it is worth it

to convert your Ham series rotor into a Ham IV if it

isn't already one. The folks at C.A.T.S. and Norm's Rotor Service

are helpful with this. They can help you figure out what

parts you need to do the conversion. The Ham IV has a better

brake

housing

and wedge, a better ring gear, and a better limit switch stop.

The Tailtwister has issues with getting stuck, and the cost

to convert a Ham IV to a T2X isn't worth it in my opinion.

The gearbox is the same; the housing is beefier, but

I believe that the main advantage is that the bolts go through the

housing, so the housing is more securely held together than in the

standard Ham IV. I found another solution to the problem of

loose bolts holding the housing together.

- The super

wedge is an improved brake wedge sold by C.A.T.S. and

is well worth installing.

- Never let your antenna coast to a halt at the south stop.

This ruins the limit switch stop. This is

especially

important with long boom yagis because they have a tremendous moment of

inertia. Fortunately on the West Coast where I live, there

isn't

too much directly south. If you let your rotor coast past

south, and the limit

mechanism

is destroyed, the top slips off the direction indicating potentiometer

and you can't tell where the antenna is pointed anymore. You

are

liable

to wrap your coax around and around. (I have to admit to

doing this myself.)

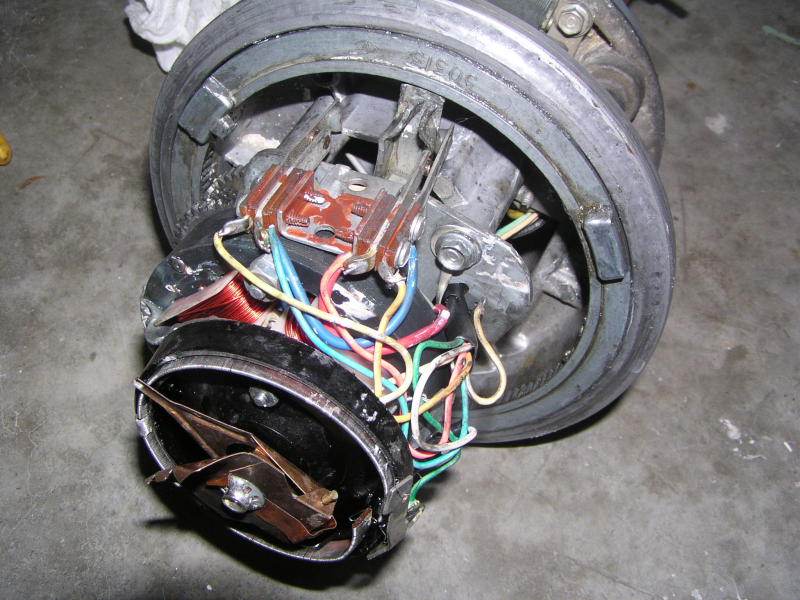

The photo

below shows the limit switch of a Ham II after it was allowed to coast

to a stop around south a

number of times. The little tab on the ring gear is supposed

to catch on the limit switch to press

open the contacts. The problem occurs when the beam's inertia

keeps the rotor turning which smashes

the tab so that it breaks the steel limit switch bar as you see.

- Mount the rotor inside the

tower if at all possible.

I have turned a four element five band quad this way.

I had this

four element quad up on a 120 foot Rohn 25G tower until the my landlord

decided

to build some apartments on the lot it was occupying.

- The bell housing is a cast part and the material isn't as

strong

as it should be to hold the bolts in. I

believe

the brake clanking on the housing tends to loosen them up.

This

is especially important to fix if you are not mounting your rotor

inside the tower. My solution to this was to use aircraft

bolts that have holes drilled in the heads so you can thread wires

through them so that they will not turn. See the disaster

photos below.

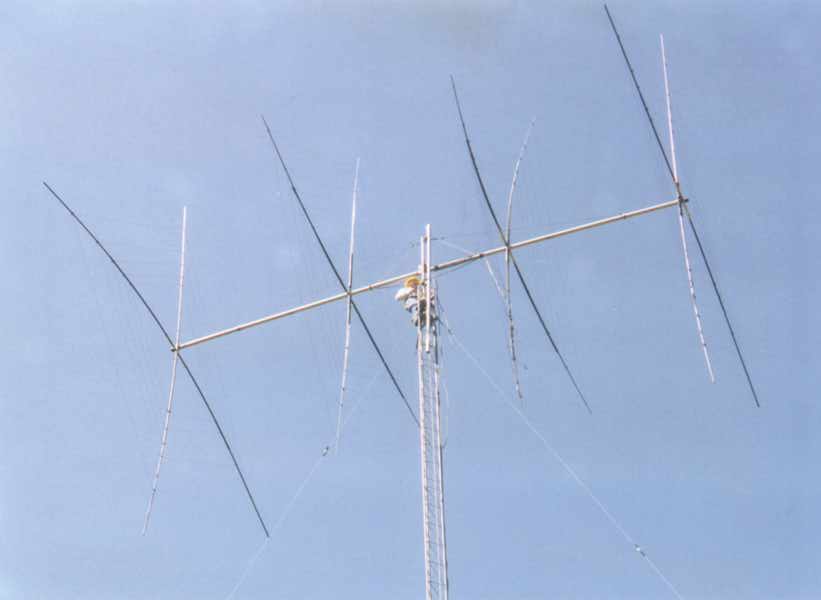

My twenty

meter monobander dangling by the coaxial cable. I found this

when I got back from a week

at the beach. I felt fortunate that that the coax held it

while I was away.

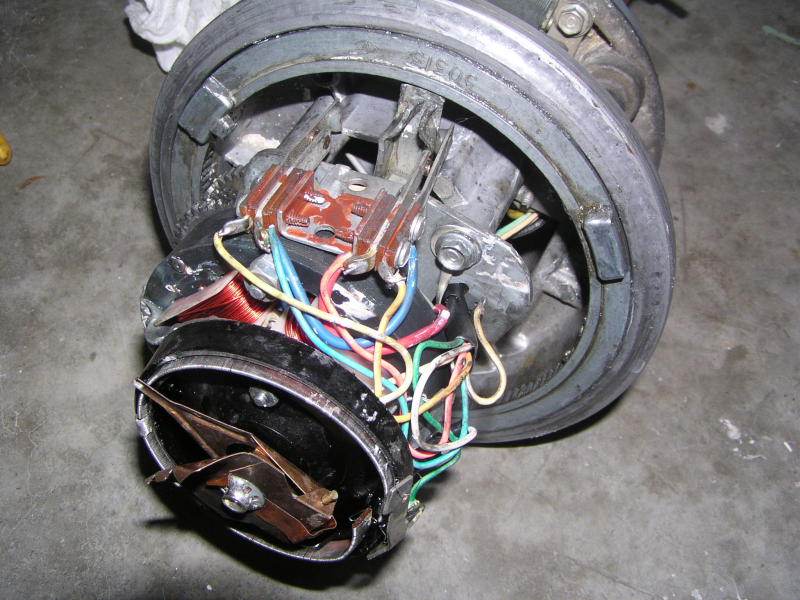

Below, you can see three bolts fell out, and one broke

off. If you look closely you can see where the

Below, you can see three bolts fell out, and one broke

off. If you look closely you can see where the

potentiometer scratched away some of the molded inside of the housing

that was supposed to hold it,

after the beam was allowed to swing past south.

- You should never use the brake to stop the rotor if you

antenna is large. The torque from an antenna with a large

moment of inertia can break the break wedge or the housing. I

have done both. Delay circuits are available if you need

them, but I feel that I can do a better job than any timer by watching

the indicator to see if the antenna has finished coasting to a stop.

- If it gets cold at your QTH, you might want to use lighter

oil than comes with the rotor. In Anchorage, Alaska where I

grew up I did that after not being able to turn my antenna when it was

colder than about twenty degrees below zero Fahrenheit.

- The manuals for the rotor are available at the Hy-Gain web site.

- It is well worth your time to solder terminal lugs to

connect the wires to the rotor, and screw them on while the rotor is on

the ground. They are much more reliable than just twisting

the wires and screwing them down. It is very difficult to repair that

kind of thing at the top of your tower.

- The gray eight wire cable doesn't last in the ultra violet

radiation and heat here in the Walla Walla, Washington area for more

than about ten years maximum. I am hoping the black stuff I

purchased a couple of years ago has a longer life.